Just follow the wrinkles!

Anytime you have a shrink film tracking issue, for example the film keeps coming out of the side sealer – Follow The Wrinkles.

As the film flows through the wrapper it is natural to see wrinkles in the film. Starting at the cross-seal bar, look at the film as it moves through the wrapper. Work your way upstream to the unwind. The point where the wrinkles increase in number, or they change angle, is the source of the problem.

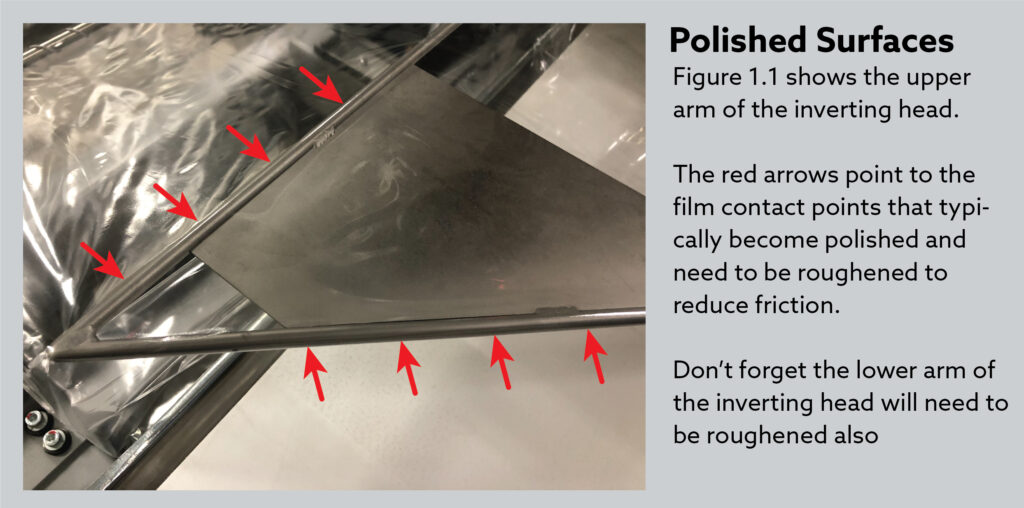

The increase in wrinkles is an indicator of drag or tension. Look for polished film contact surfaces, misalignments, and debris.

Polished film contact surfaces, like the inverting heads are caused by the abrasives in the films. The polished surface has greater surface area creating drag on the film. This happens over a course of time and is normal. To correct this, roughen the surface with emery cloth or very fine sandpaper. This reduces the surface area of the contact piece and allows the film to flow more freely over the surface. Perform this as needed anytime you see a polished film contact surface.

Misalignment of a film contact device is one of the most common causes of film tracking issues. There are two layers of film flowing through the machine, one above and one below the product. It’s important that their travel path is equal. Ideal settings are: Side Seal Alignment – the height of the side seal should have the film plane (where the upper and lower tracking belts of the side seal meet) at the center of the package.

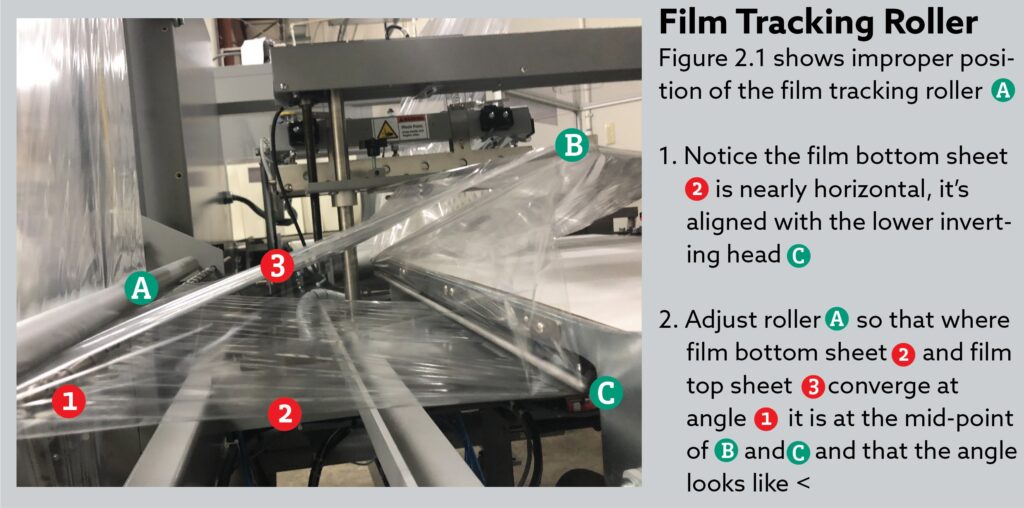

Film Tracking Roller – The last roller the film touches before the inverting head should be adjusted so the film plane is equidistant between the upper and lower inverting head bars.

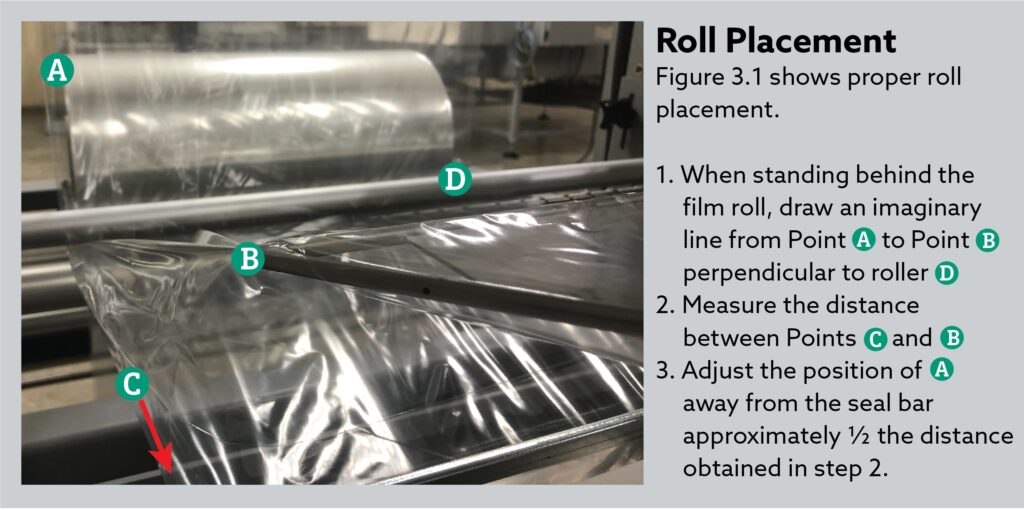

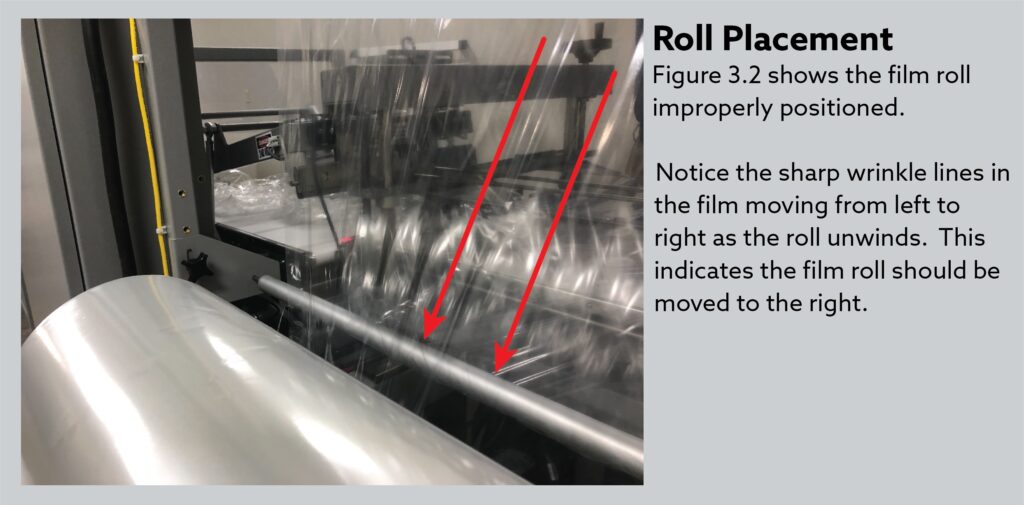

Roll Placement – The edge of the film roll should not be inline with the edge of the inverting head. Instead, move the roll upstream (away from the seal bar) about ½ the distance between the upper and lower inverting heads – if the upper and lower inverting heads are 4” apart, move the film roll so the edge is approximately 2” upstream from the end of the inverting head.

Following these steps and taking a systematic approach to correct film tracking issues makes troubleshooting easy. Remember to start at the cross-seal bar, look at the film as it moves through the wrapper. Work your way upstream to the unwind. The point where the wrinkles increase in number, or they change angle, is the source of the problem.

Be sure to check out our post on Troubleshooting End Seal Issues? and view other stretch wrapping solutions Orion Packaging can offer, from pharmaceutical, to food and beverage, to specially designed units.